Do you remember when printers were just for homework assignments or family vacation photos? It’s hard to believe how far we’ve come. Today, technology has flipped the script, and printers can now do far more than produce documents or pictures on paper. Enter the world of 3D printing, or additive manufacturing. This groundbreaking technology is changing how industries operate and opening up new, exciting career paths. But what exactly is 3D printing, and why is it so revolutionary? Let's break it down and explore its incredible potential.

What is 3D Printing?

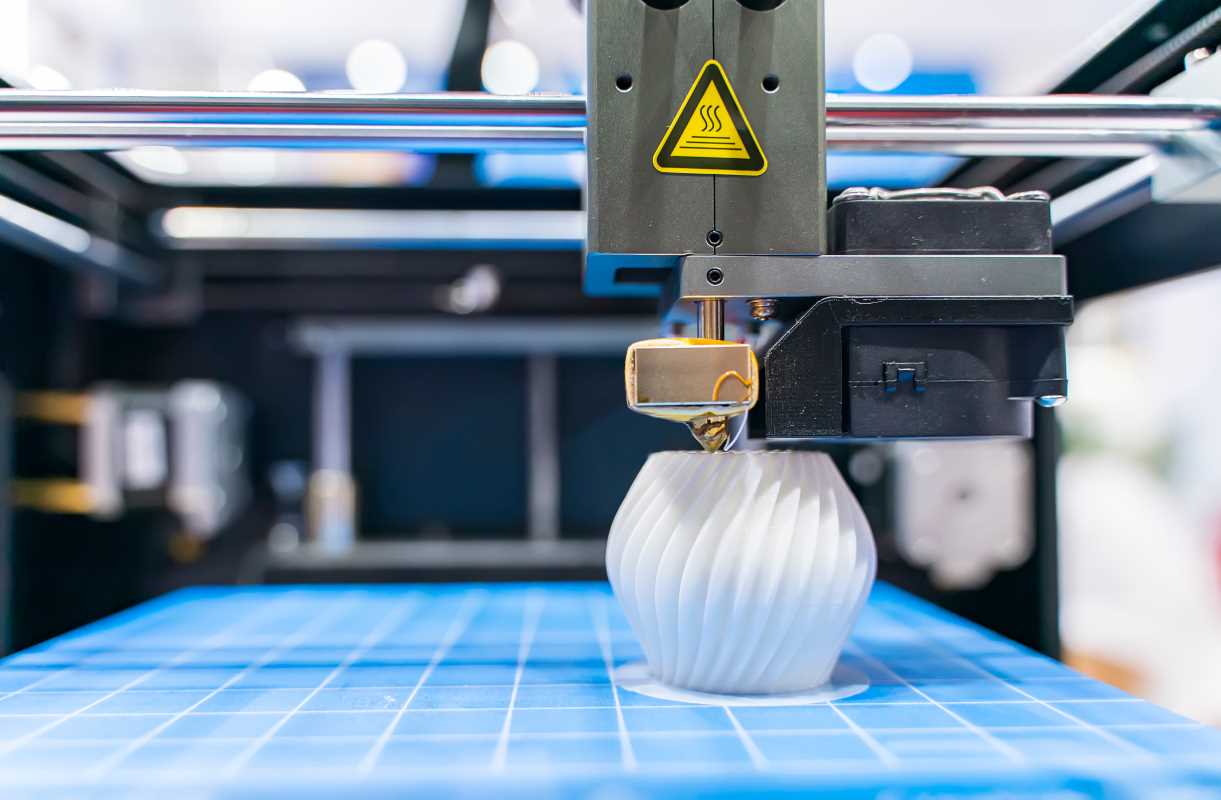

At its simplest, 3D printing is the process of making three-dimensional objects from a digital file. This is done layer by layer, using materials such as plastic, metal, resin, or even edible substances. Instead of relying on traditional manufacturing methods like molding or carving, 3D printing builds objects from the ground up, one fine layer at a time.

It all starts with a 3D design. Using software, designers create digital blueprints that specify every detail of the object, from its shape to its size. Once the file is ready, it’s sent to a 3D printer, which translates the design into physical form. Imagine pressing "print" on your computer and watching that blueprint materialize in real-time. From a futuristic phone case to intricate sculptures to functioning machine parts, the diversity of objects you can create is almost limitless.

People are constantly pushing the boundaries of what’s possible. For example, while most people associate 3D printing with plastic, the reality is far more diverse. Some creative chefs are experimenting with food printers to make artistic desserts, while researchers are working on printing human tissue for medical purposes. It’s not an exaggeration to say that 3D printing is transforming what's possible in almost every realm of life.

Industries Revolutionized by 3D Printing

It’s no surprise that 3D printing has captured the attention of so many industries. Its ability to produce complex designs efficiently, save costs, and push the limits of traditional manufacturing is nothing short of revolutionary. Here are some of the major industries experiencing a 3D printing renaissance:

1. Healthcare

The medical field is one area where 3D printing has had a massive impact. Imagine a world where doctors can create custom implants tailored to your body or print life-saving medical devices in hours instead of months. That’s the potential of 3D printing in healthcare.

For example, hospitals now use 3D printers for creating orthopedic implants and prosthetics customized for individual patients. These tools don’t just improve health outcomes but also return dignity to people recovering from physical setbacks. Even hearing aids and surgical instruments can now be 3D printed, with designs perfectly suited to a patient's anatomy.

One of the most promising areas involves bioprinting, where researchers are experimenting with printing human tissue. Though still in its early stages, the dream of creating organs like kidneys or hearts from a machine is becoming more realistic each day. Some surgeons also use 3D-printed models for surgical planning, allowing them to practice complicated procedures before stepping into the operating room.

2. Aerospace and Automotive

Building rockets, airplanes, or cars often involves incredibly complex, custom-made parts. Traditional manufacturing can be time-consuming and expensive, but 3D printing provides a faster and more efficient alternative.

Aerospace companies like SpaceX and Boeing are now using 3D printers to fabricate engine parts and other components that can withstand extreme environments. NASA, for instance, has used 3D printing to manufacture rocket parts designed for deep space exploration. These parts are not only lighter and more durable but also cost far less to produce.

Similarly, car manufacturers are using 3D printing technology to produce spare parts, prototypes, and even entire vehicle components. The automotive industry benefits from 3D printing's ability to create lightweight yet strong materials, which help make vehicles more fuel-efficient. Motorsports teams, like those in Formula 1, also heavily rely on this tech to create aerodynamic car parts quickly to gain a competitive edge.

3. Fashion and Art

Think fashion is all about old-school craftsmanship? Think again. Designers who use 3D printing are creating some of the most groundbreaking and experimental pieces in the industry. From intricate jewelry to custom-fit dresses, the ability to mold designs directly from computer files allows for unprecedented creativity.

Some runway pieces take advantage of materials that can be shaped into forms traditional sewing and stitching can’t achieve. Shoes can now also be tailored to perfectly fit an individual’s foot size using 3D-scanning technology.

Artists, too, are harnessing the power of 3D printing. Sculptors and creatives worldwide use the technology to construct complex installations, architectural models, and interactive exhibits. These pieces push the boundaries of what can typically be achieved using manual techniques, creating new opportunities for immersive art experiences.

4. Construction

Building a house layer by layer? It might sound like a sci-fi story, but it’s already happening. Companies are using massive 3D printers to create structures out of concrete-like materials. These "printed" homes can be built faster and often cheaper than traditionally-built homes, making them a potential game-changer for solving housing crises.

Beyond residential properties, 3D printing in construction is also making headlines for its applications in disaster relief. Temporary shelters, schools, and medical buildings can now be created quickly in areas affected by natural disasters. It’s a sustainable, innovative way to address global infrastructure challenges.

5. Food

Yes, you can 3D print dinner! This application is equal parts functional and fun. With edible printing materials like chocolate, sugar, or dough, chefs can create personalized dishes or futuristic food art. Whether it’s a chocolate sculpture that looks too good to eat or pizza made to order at interactive restaurants, food printing brings customization to the culinary world.

For the food industry, however, the real innovation lies in sustainability. Scientists are exploring ways to produce protein-packed meat substitutes or nutritious snacks in an efficient, eco-friendly way using printers. This could address global issues like food scarcity and waste.

New Careers in 3D Printing

The rise of 3D printing has also sparked the emergence of specialized career paths. If you’re someone who loves the idea of blending technology with creativity, this might just be the perfect field for you. Here are some of the roles driving this industry forward:

- 3D Design Specialists

- Every 3D-printed object starts with a digital blueprint. Designers play a critical role in imagining and formatting these objects, whether they’re jewelry, prosthetics, or car components. Mastery in design software is key for these professionals.

- Additive Manufacturing Engineers

- Engineers in this role focus on perfecting the printing process. They ensure machines are operating efficiently and that finished products meet the required specifications.

- Material Scientists

- Every material has unique properties that influence its use in 3D printing. Material scientists innovate and test new materials, like flexible plastics, temperature-resistant alloys, and biocompatible substances for medical use.

- 3D Printer Technicians

- These professionals keep everything running smoothly. From maintaining the printers to troubleshooting errors, their in-depth technical know-how keeps the gears of the 3D printing world turning.

- Sales and Marketing Experts

- Not everyone knows the true potential of 3D printing, so connecting this tech to its audiences is critical. Sales reps, marketers, and business developers bridge the gap between innovation and customers.

These roles each require a blend of creativity, problem-solving, and technical expertise. No matter your specific interest, there’s likely a 3D printing career that aligns with it.

Challenges and Opportunities

Of course, no technology is without limitations, and 3D printing is no different. While accessibility has improved, commercial-grade printers and materials often remain expensive for individuals and small businesses. Print times, depending on the complexity of a project, can also be slow. Larger objects or intricate designs can take hours, days, or even weeks to produce.

There’s also the challenge of environmental sustainability. While 3D printing often reduces overall waste in manufacturing, most printers rely on plastics that aren’t biodegradable. Innovating greener and more recyclable materials will be critical as this technology continues to grow.

Despite these challenges, the opportunities far outweigh the hurdles. As the technology becomes more widespread, costs will likely come down, making it easier for individuals and small businesses to hop onboard. Advancements in material science and printer design also show promise for overcoming current limitations.